Author: Smartfix UK

A very common request when we discuss customers’ requirements for their van installations is for a "big compressor". This will usually refer to the air receiver size and requests for 100, 150 or even 200 litre tanks are not uncommon. Here’s a rundown of everything you need to know about compressor installations.

Types of Compressor Installations

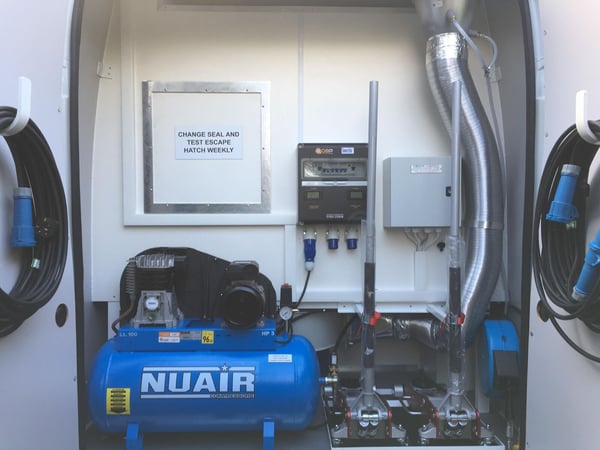

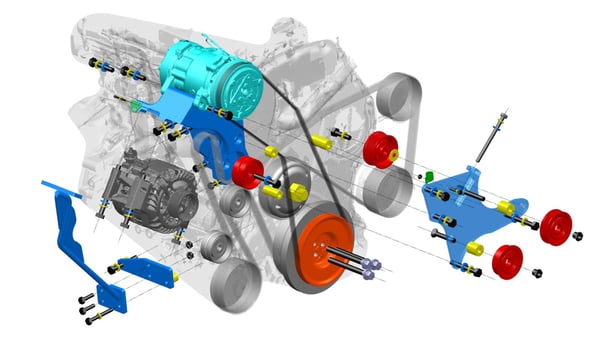

A compressor installed into a mobile workshop will nearly always be limited to 3 horsepower and 2200 watts so it can be powered by a domestic power supply. There are some exceptions to this, though, such as engine mounted compressors or petrol/diesel compressors.

For the vast majority however, it will be a 3HP, 2.2kW motor. The specification for such compressors will state their output in CFM (cubic feet per minute), which essentially means how much air it can pump out. Typically, a 3HP compressor will produce up to 12 CFM displacement.

However, it is important to look at the Free Air Delivery (FAD) as this is the amount of air that will actually be available to use for your tooling. With that in mind, we can look at why the size of the air receiver isn't as important as you may think.

Size doesn’t always matter!

In terms of air consumption, the tool that typically causes the biggest issue is usually the air fed sander or "DA". For instance, the Mirka 77mm palm Sanders requires 481 litres of air per minute. As a guide, the average 3HP, 2.2kW compressor will produce about 260 litres per minute.

Importantly though, although the spec may state 360 LPM, this refers to the pump displacement. To ensure the correct specification for the compressor, the FAD (Free Air Delivery) must be considered; this is approximately 70% of the Stated CFM.

This is why most air compressors used in vans are not even close to being able to supply enough air for an air fed Sander.

Air receiver compressor considerations

Crucially, the air receiver compressor needs to be taken into account as this provides a storage of air for the tools to use. Although, by using the Mirka sander as an example, even a 200 litre receiver would be completely empty after only 25 seconds use. Once the receiver is empty, the air sander would be demanding a supply more than 200% above the compressor motor’s capacity, which is far from ideal.

The solution is to ensure that the air output of the air compressor installation is sufficient to supply the equipment you want to use. If this is done properly, then the size of the air receiver tank is less important. In the example above, a simple solution here would be to switch to the electric version of Mirka’s sander. However, if the tooling being used requires more than 300 litres of air per minute, it is likely that a different type of compressor would need to be considered such as engine mounted or petrol/diesel.

Get in touch with our Compressor Installations experts today

As part of our van build design process, SMARTFIX will assess your specific requirements and ensure that all the equipment is designed to work together. In our mobile workshops we can supply everything from conventional 3HP units to engine mounted compressors that can supply 30CFM of air as part of our compressor installation service.

Whatever service you are looking to offer from your van, contact our specialist compressor installation experts today to ensure you have the right tools and the right system in place for your mobile repair service.